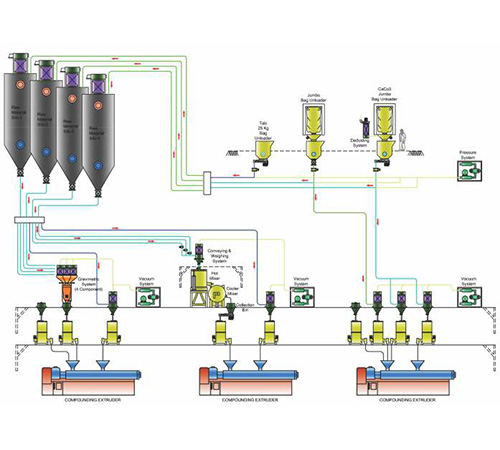

Masterbatch Compounding

- Most suitable for wide range of polymer master-batch compounding applications like, black, white, filler, engineering, automotive.

- Reduces rejection, spillage, wastage & man-power dependency.

- Fastest & easiest grade changes & reduces down time.

- Can be easily integrated with all make of compounding extruder, loss in weight feeders, process blenders & kneaders.

- Modular design for future expansions.

- European engineering delivered most suitably for India users.

- Automatic material distribution & Re-filling from PLC control.

- Customized Re-fill solutions available for variety of materials.

- Complete data logging for break down analysis.

- Complete turn key solution for before extrusion & after extrusion material handling.

- Suitable for Mixers of 125 kg/ Batch to 5000 Kg/ Batch

- Can deliver material to extruders ranging from 50 kg/hr to 1500 kg/hr

- Raw material storage silos available from 5 M3 to 500 M3 capacity

- Recipe storage silos from 5 M3 to 100 M3 capacity.

- 7 Inch & 10 Inch controller size available.

- Controller available with Mode-bus, Power-link, OPC UA/ DA, Profi-Net, Profi-bus for seam less integration possibilities.

- Suitable for Polymer & rubber granules,ATH, Talc, Mica, TiO2, MgH, CaCO3, wood Saw dust, Rice Husk, Dolomite & Calcite bulk handling.

- Liquid storage & dosing, weighing suitable for DOP, DINP, NPP, CPW.

Rubber Compound

White MB

Automative

Black MB

Filler MB

Prasad Pneucon Solution Pvt. Ltd.

Bulk Material Handling Systems for PVC and other Powdery material